Product Overview

The Kombi grader is used for the inexpensive, effective maintenance and new construction of water-bound paths, field paths, hiking trails and cycle paths, construction roads or country lanes. It is perfect for removing potholes, weeding, grading, re-profiling and loosening paths made from a wide range of bulk materials such as gravel, crushed stone, chippings or sand.

Rational path maintenance

When using the grader on water-bound road surfaces, excess or previously deposited material is picked up by the HARDOX scraper bar and carried along in the u-shaped frame of the grader. This material fills existing holes and unevenness, is smoothed out by the rear scraper of the grader and statically compacted by the roller. The path is now leveled and reconsolidated. The machine only takes up as much material as needed, thus saving the use of expensive new material.

Powerful path maintenance

The high hourly output of the HK grader enables powerful, cost-effective use with simple operation. Even heavily used road surfaces can be maintained easily.

Ripper bar

The optional ripper bar fitted with carbide metal chisels loosens up heavily compacted road surfaces. Existing material is thus processed and reinstalled and interlocked with the grader in those places where it is missing. Creating and maintaining the roof profile can be achieved by adjusting the grader body, which can be swiveled around its longitudinal axis, and the distributor blade, which is set at an angle to the direction of travel, allowing an exact roof profile to be created for rapid drainage of surface water.

Mechanical weed control

The grader can do on water-bound surfaces what hot water, steam, infrared and co. cannot do: Sustainable, effective weed control without long set-up times and without the use of chemicals!

- Working width: 130 cm

- Weight: 400kg

- Power requirement: from 35 hp

- Lateral offset mechanical: option

- Distribution shield: option

- trailing roller : standard

- Ripper Bar : option

- lighting : standard

Articles on Gravel Maintenance

Accessories

Applications

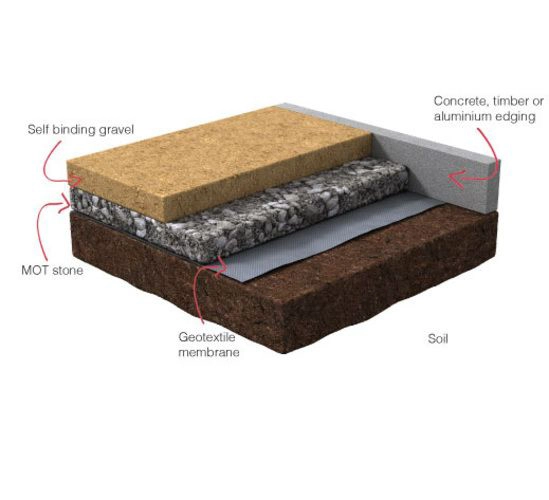

Gravel paths come in many forms, usually particular to different geographic regions where a certain type of stone is available. This presents several different challenges when looking at different types of gravel surface. The main consistent features we are trying to promote are easy drainage through the surface, even distribution of material and reduction of weeds. The Gravel Path Grader helps to deal with all these issues.

05497a248f15.jpg)